October 2024

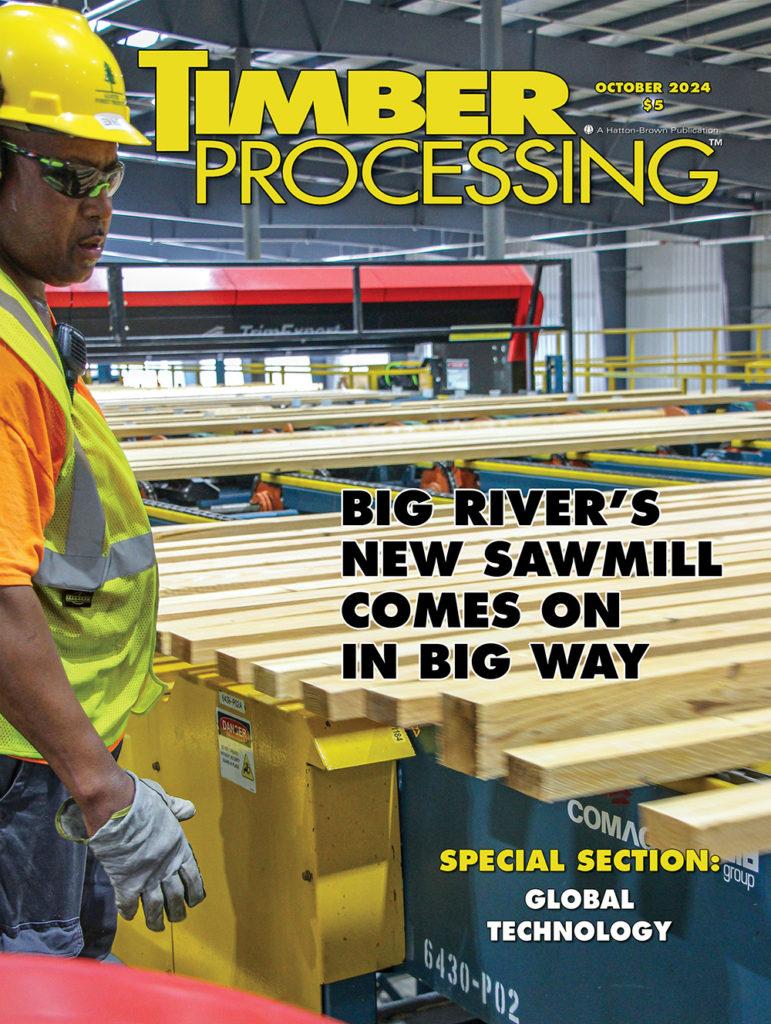

Cover: Big River’s New Sawmill Comes On In Big Way

Two years after breaking ground in Gloster, Miss., Big River Forest Products (Claw Forestry) has its high production SYP sawmill running strong and contributing to the company’s ever growing sawmill roster.

Inside This Issue

COVER: Big River's New Sawmill Comes On In Big Way

Two years after breaking ground in Gloster, Miss., Big River Forest Products (Claw Forestry) has its high production SYP sawmill running strong and contributing to the company’s ever growing sawmill roster.

THE ISSUES: Let's Hear It For The Upcomers

I first met Dan Anderson in Oklahoma, where he’d climbed up the ladder at his hometown sawmill. I enjoyed the visit, as I interviewed him about the facility. We walked around while I shot photos. As lunchtime approached, naturally we had a good back and forth about BBQ—I, a Southern girl through and through, love me a good pulled pork nacho plate. We decided to go to a spot he said was the best in all of Oklahoma. The food was good, and the company was great.

Article by Jessica Johnson, Senior Chief, Timber Processing

NEWSfeed

- Canada Challenges Lumber Duties

- Canfor Closures Causing Ripples

- Timberlab Picks Millersburg

- Bid Group Becomes Comact

GlobalTech

- Comact

- Combilift

- Easy-Laser

- Finnos

- Joescan

- Ledinek

- Lico Machinery

- Limab

- McDonough

- Mebor

- Minda

- Sennebogen

- SGM Industry

- TS Manufacturing

- USNR

MACHINERY Row

- Bright Wood Has An Advantage

AT Large

- Roseburg Appoints Hamill As COO

- Starfire Helps Found Community Health Fund

Find Us On Social

The Issues: Let’s Hear It For The Upcomers

Article by Jessica Johnson, Senior Chief, Timber Processing

I first met Dan Anderson in Oklahoma, where he’d climbed up the ladder at his hometown sawmill. I enjoyed the visit, as I interviewed him about the facility. We walked around while I shot photos. As lunchtime approached, naturally we had a good back and forth about BBQ—I, a Southern girl through and through, love me a good pulled pork nacho plate. We decided to go to a spot he said was the best in all of Oklahoma. The food was good, and the company was great.

See, Anderson and I are not only similar in age, and in how we got our starts in this industry coming from the outside. But we are also similar in that we really care about the people we work with. My fellow TP editors are the older brothers I didn’t know I needed. Anderson shared similar sentiments about the mill in his hometown being a special group. I left the lunch thinking that Dan Anderson was definitely going to be a mill manager to watch over the years.

So, last month, I was not the least bit surprised when I walked into the conference room of Big River Forest Products, Gloster, Miss., and sitting next to my friend (and Big River COO) Tommy Stansell was his new mill manager (officially general manager), none other than Dan Anderson. As we moved through the process of talking about the new state-of-the-art turnkey sawmill provided by Comact I could see that, again like me, Anderson had grown up a little in the five years since the last time I saw him. His knowledge was exponential! But, also like me, his caring nature hadn’t been dulled by cynicism.

When I asked him what his favorite part of being involved in a greenfield startup was, he didn’t hesitate: “My favorite part is the people.” His people were also one of the biggest challenges he told me. Not only was he (and everyone else) learning new equipment, but they were learning each other. And with a staff of more than 100 that’s a lot of new faces.

Anderson credits Comact and their team for really supporting the Gloster team on the ground with training, which helped the Gloster team get processes in place to set the sawmill up for success. “We want to make sure we are continuously evolving,” he emphasized to me about the new technology—some of which has the Comact machine learning AI.

In the end I asked him if he had to do it over again, would he do it the same? The answer was an easy and resounding yes.

Stories like this, companies like Big River, people like Stansell and Anderson, are a reminder that the industry has good people entering the meat of their careers who are excited about innovating and are committed to producing quality lumber for generations to come.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.