Most Lumbermen Remain Optimistic

Article by Rich Donnell, Editor-in-Chief, Timber Processing June 2022

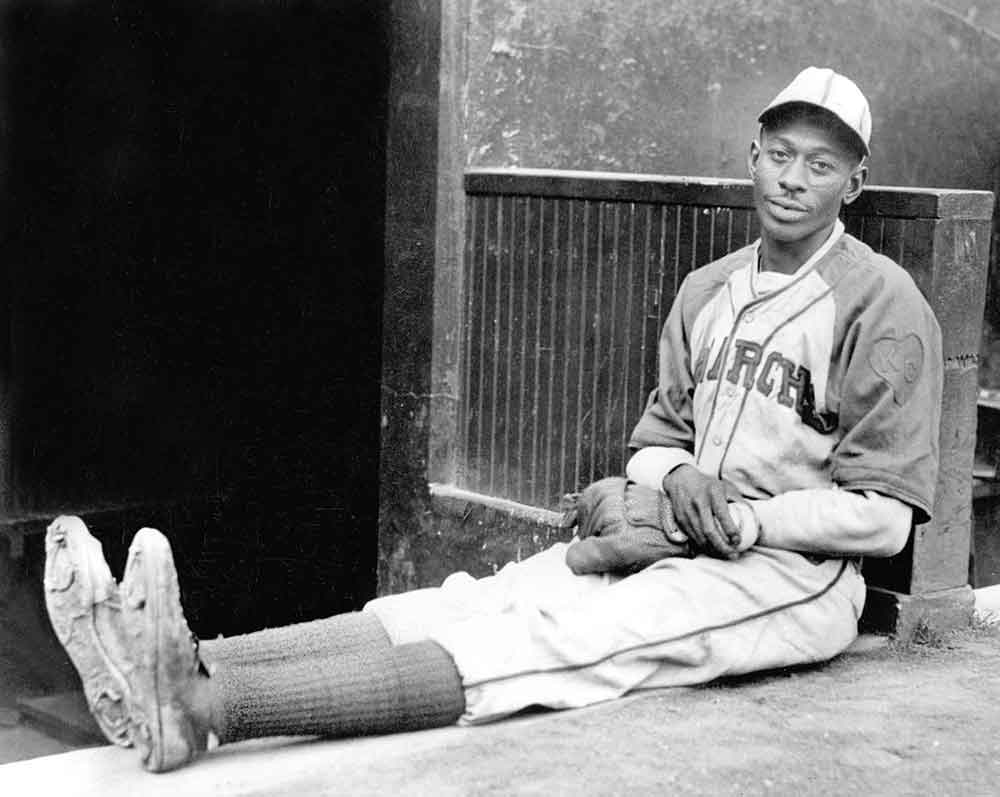

The great and colorful Satchel Paige, who pitched more than 20 years in the Negro Leagues before winding down his career pitching five seasons in the Major Leagues, delivered one of the most famous quotes not only from a big league ballplayer but from anybody: “Don’t look back. Something might be gaining on you.”

He never explained what he meant by it. Perhaps he meant to keep moving forward because if you turn around and look back you’ll lose ground and momentum; or he could have been referring to Father Time catching up; or maybe he was referring to past mistakes in life which if given the chance could rear their ugly head again; or given the racial injustices of his time, there’s probably somebody back there ready to do some damage.

As we recently dove into the responses to our 2022 Sawmill Operations & Capital Expenditure Survey, the quote from Satchel Paige entered my mind and never left it. This probably makes me a glass-half-empty kind of person.

After all, the results from the survey were quite positive overall. Elsewhere in this magazine you’ll find two stories, one on the results from the softwood lumbermen and the other on the hardwood lumbermen, both articles filled with lots of graphs and quotes.

If you combine the results of softwood and hardwood lumbermen, representing about 230 sawmills, you find that 81% of them forecasted their lumber business situation for 2022-2023 as excellent (16%) or good (65%). If you read the individual stories, you’ll see that the softwood lumbermen were generally more optimistic than the hardwood lumbermen, but the combined percentage is still pretty impressive. Another 15% forecasted as fair, and 4% said poor.

In addition, lots of capital expenditure projects have recently been completed or are ongoing. For example, 68% had completed a project in the past year. And looking ahead to 2022-2023, more than 40% had committed at least $1 million to capital expenditure on machinery and systems, with 13% of those planning to spend more than $10 million. In other words, there are big projects in the works, and as the survey also indicated, new mills are still being built and several companies are thinking seriously about building a new mill.

The post-COVID building surge did create some issues, according to the survey, especially with supply chain disruptions, labor shortage, and parts availability. But these were issues caused by strong economics. It has been anything but business as usual.

As the lumbermen were completing the survey this spring, rising inflation and interest rates began causing concerns, though the homebuilding markets still showed a lot of steam.

This brings us back to the Satchel Paige quote. Lumbermen have had such a good run, especially with regard to lumber pricing, that while they perhaps even expect something might be gaining on them, who can blame them for not wanting to look back just yet?

Why ruin a good thing?

Latest News

Lumber Quality Workshops Announced

Terry Brown and the Lumber Quality Institute will again offer two lumber quality-related workshops in Salem, Ore. for the sawmill industry in November 2023. The Lumber Quality and Process Control Workshop will be held November 6-7, and the Lumber Quality Leadership Workshop will be held November 8-9…

BID Group Starts Apprenticeship Program

In a significant development for the local community, BID Group has collaborated with the Dept. of Labor and Apprenticeship Carolina to launch a groundbreaking apprenticeship program in its Fabrication Shop. The program provides valuable opportunities for aspiring professionals in the manufacturing sector…

U.S. Housing Starts Fall While Building Permits Rise

U.S. housing starts fell in August from July, at a seasonally adjusted rate of 1.283 million, down 11.3%. Single-family starts were at a rate of 941,000, 4.3% below July, while multi-family starts were the primary culprit at 334,000, down 26.3%, according to the U.S. Census Bureau and U.S. Dept. of Housing and Urban Development monthly new residential construction report…

Canfor Puts ‘Stock’ In New BC Facility

Vancouver, BC-based Canfor Corp. is investing $200 million to build a new state-of-the-art manufacturing facility in Houston, British Columbia, which will have an annual production capacity of 350MMBF. “I’m very pleased to be making this announcement in British Columbia, where Canfor has been proudly headquartered for 85 years,” comments Don Kayne, President and CEO. “This decision comes following…

Find Us On Social

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.