KDS Windsor Offers CDK Virtual Tour

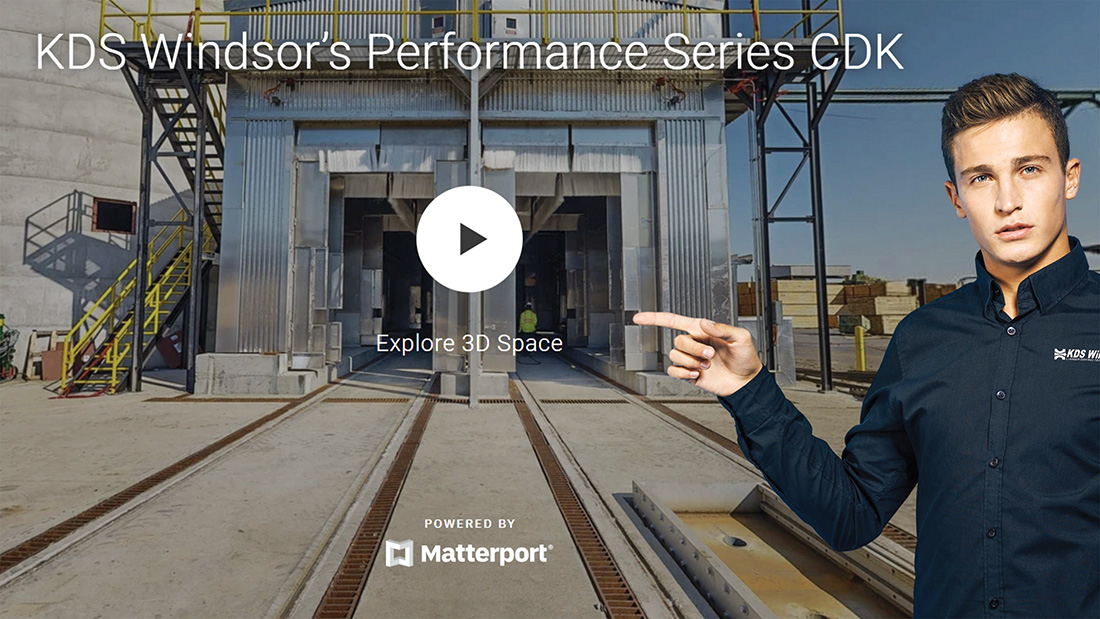

KDS Windsor is offering a virtual tour of a recently completed installation of its continuous dry kiln designed to deliver an annual production of 150MMBF at a sawmill in Greenville, NC.

KDS Windsor is offering a virtual tour of a recently completed installation of its continuous dry kiln designed to deliver an annual production of 150MMBF at a sawmill in Greenville, NC.

The CDK system incorporates KDS Windsor’s patented DrySpec and DryTrack technology, featuring a robust reverse flow double-track design, and integrating several phases—preheating, drying, cooling, equalizing, and conditioning—within a single extended chamber.

Advanced control and monitoring systems maintain precise moisture and temperature levels, ensuring consistent output and high-grade lumber quality.

The Matterport virtual tour of the installation, https://www.kdskilns.com/virtual, features a user-friendly menu, allowing visitors to navigate to specific kiln components. Each area is enriched with tags, providing pictures, videos, and detailed text that highlight the kiln’s advanced features and functionality.

The installations also includes a 50MMBTU green sawdust gasification burner.

Latest News

Mendocino Companies Expands In Utah

Mendocino Companies purchased the assets of Utah Wood Preserving (UWP) and portions of its affiliates. UWP’s manufacturing facility in Woods Cross, Utah, is a well-maintained preservative treating plant on a large, fully paved site with dry kilns and rail service…

Structurlam Looks To Reboot

The temporary closure of Structurlam Mass Timber’s Conway, Ark. cross-laminated timber (CLT) and glulam plant and the apparent severing of the plant’s relationship as a major supplier for Walmart’s new low carbon footprint and energy efficient corporate…

Coalition Supports Duty Upgrade

U.S. Dept. of Commerce announced the preliminary determination of a combined anti-subsidy and anti-dumping duty rate of 8.24% in the fourth annual review of allegedly subsidized traded Canadian softwood lumber imports into the U.S. The review covers…

Canfor Plans New BC Sawmill

Canfor Corp. stated that to better align manufacturing capacity in British Columbia with the available long-term fiber supply, it is restructuring its BC operations by permanently closing its Chetwynd sawmill and pellet plant and temporarily closing its Houston sawmill for an extended period to facilitate…

Find Us On Social

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.