KDS Windsor Offers CDK Virtual Tour

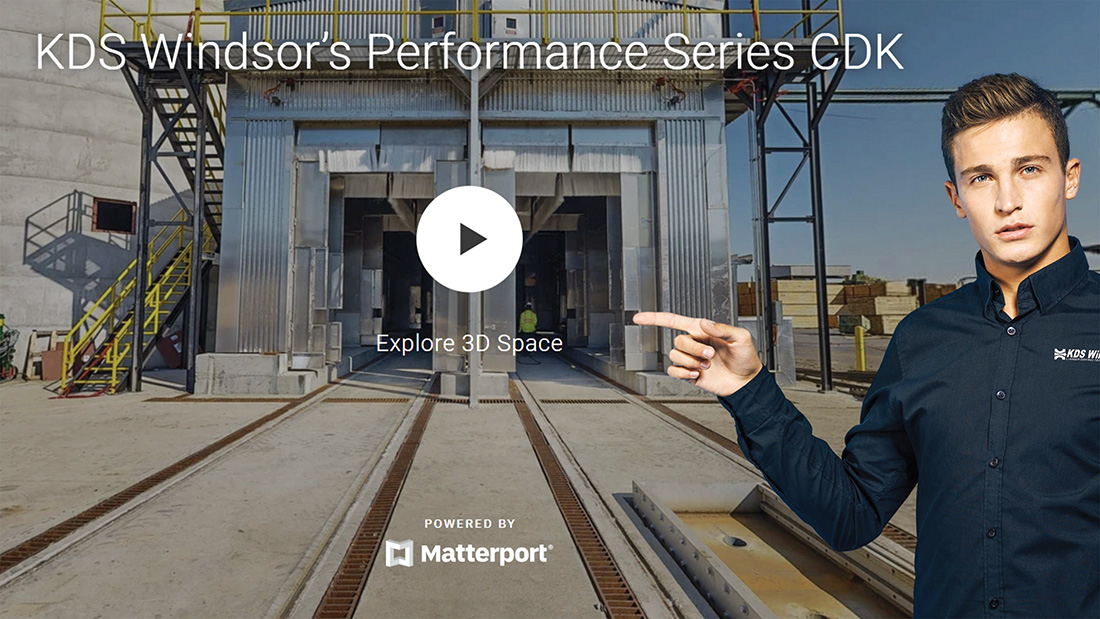

KDS Windsor is offering a virtual tour of a recently completed installation of its continuous dry kiln designed to deliver an annual production of 150MMBF at a sawmill in Greenville, NC.

KDS Windsor is offering a virtual tour of a recently completed installation of its continuous dry kiln designed to deliver an annual production of 150MMBF at a sawmill in Greenville, NC.

The CDK system incorporates KDS Windsor’s patented DrySpec and DryTrack technology, featuring a robust reverse flow double-track design, and integrating several phases—preheating, drying, cooling, equalizing, and conditioning—within a single extended chamber.

Advanced control and monitoring systems maintain precise moisture and temperature levels, ensuring consistent output and high-grade lumber quality.

The Matterport virtual tour of the installation, https://www.kdskilns.com/virtual, features a user-friendly menu, allowing visitors to navigate to specific kiln components. Each area is enriched with tags, providing pictures, videos, and detailed text that highlight the kiln’s advanced features and functionality.

The installations also includes a 50MMBTU green sawdust gasification burner.

Latest News

Industry Says Goodbye To Walter Jarck

Walter Jarck, whose career in the forest products industry spanned 65 years and ranged from logging machinery to engineered wood products, died January 3, surrounded by his children, in North Wilkesboro, NC. He was 92.

Carbotech Acquires Sawquip

Carbotech Group has acquired Sawquip, a manufacturing company specializing in the design and manufacture of sawmill equipment for the primary and secondary breakdown of logs into lumber. This acquisition allows Carbotech Group to add on a new field of expertise, providing customers with innovative new solutions for lumber production. Sawquip’s innovative products include log turners and optimized log infeeds, chipping canters, twin and quad circular saw modules, as well as optimized gangs for controlled shape sawing, among others.

Oregon Truckers File Suit Against State

Rob Freres, president of Oregon-based Freres Engineered Wood, a manufacturer of lumber, veneer, plywood and mass timber, has thrown in his support for a lawsuit filed by the Oregon Trucking Assn. and three Oregon-based trucking companies against the state of Oregon for overcharging truckers under the weight-mile tax.

Hasslacher Enters North America

Austria-based Hasslacher group is acquiring a stake in Element5, a mass timber producer specializing in the design, manufacture and assembly of modern engineered timber buildings. Based near Toronto, Can., Element5 employs more than 100 and produces cross-laminated timber and glued laminated timber for the North American market.

Find Us On Social

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.