January/February 2023

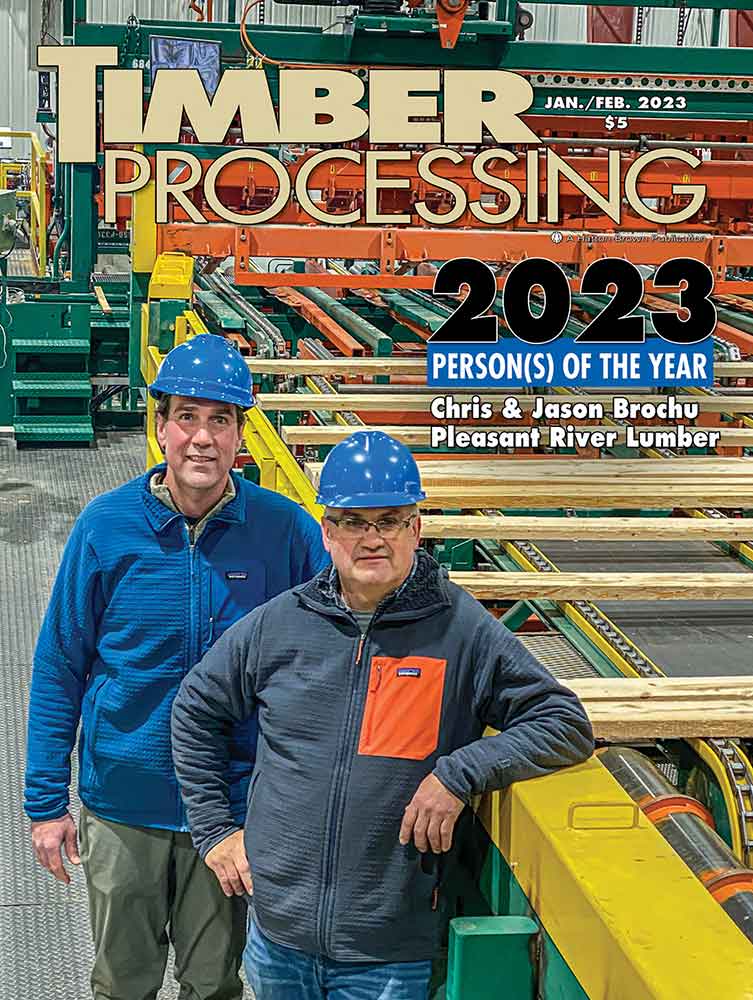

Cover: 2023 PERSON(S) OF THE YEAR

DOVER-FOXCROFT, Maine – While greenfield sawmill announcements have dominated the sawmill news cycle in recent years, another approach was being executed in the Northeastern corner of the U.S., where Pleasant River Lumber Co. was gathering lumber mills, timberland, and other diversified forest products interests like Southern squirrels do for the winter. Today, Co-Presidents and brothers Jason and Chris Brochu lead a family business of more than 800 employees.

Inside This Issue

THE ISSUES: Two Brothers, One Big Family

I am going to start this one like I always do—by talking about myself and my family. Stay with me. I am the Person of the Year specialist. I love these stories. I love talking about why a person does what they do. How they help their community in big ways and in small ones. I often wonder how many t-ball teams are out there with “Such And Such Lumber” proudly displayed on the front of their jerseys. This story each year reminds me why I love this industry. After I pulled out of the Pleasant River Lumber Enfield (Maine) location, I immediately voice dialed my mother.

Article by Jessica Johnson, Senior Editor, Timber Processing

NEWSfeed

- Vaagen Pinpoints Midway Closure

- Black Hills Takes Another Look

- West Fraser Idles Perry Sawmill

- Softwood Lumber Board Announces Lineup

- Forest Project Moves Ahead

- Proposed Pellet Mills Advance

- Treating Giant Plans Expansion

- Clutter Was Resources Expert

- Sumitomo Plans Components Plant

Woods To Mill

FREEBURG, Missouri – Skidmore Lumber Co., which includes sawmill and logging operations, is a family business. Current owners Howard, 62, and Doug Skidmore, 60, bought out the shares of their oldest brother, Odis, in 1992 and their dad, Oreal Skidmore, in ’94. Doug and Howard each play an active role at Skidmore Lumber.

Article by David Abbott, Senior Editor, Timber Processing

Advanced Pneumatic Control

In the early days of timber harvesting, log jams were a common site as felled trees floated downriver on the way to the sawmill. In today’s modern sawmills, however, log jams equate to equipment downtime, lost productivity, reduced profits and even potential safety risks. For one Canadian lumber company, upgrading the pneumatics on its Sawquip sawline vertical press roll actuators helped make log jams a thing of the past while increasing performance, lowering maintenance and saving air consumption.

Article submitted by Emerson. Francois Tremblay is a technical expert in the sawmill industry and Alexandre Girard is a technical specialist for pneumatics and motion control at Emerson.

ATlarge

- Snider Industries Names Fleming Plant Manager

- SFPA Announces Communications Manager

- Oregon Dishes Out Timber Revenue

- Arkansas Group Gains USDA Bottomlands Grant

- Timber Companies Will Combat CWD

- Long-Running SAF Project Has Life

- PotlatchDeltic Sets GHG Emissions Targets

- Biochar Plant Chips Feedstock Will Come From Nearby Sawmill

MACHINERYrow

- Sawmill Camera Hit By A Log

- Peak North America Acquires Endurance Equipment

- Lampe & Malphrus Goes With USNR End Dogging

- Opticom Celebrates 50th Anniversary

Find Us On Social

2023 PERSON(S) OF THE YEAR: CHRIS & JASON BROCHU, PLEASANT RIVER LUMBER

Article by Jessica Johnson, Senior Editor, Timber Processing

DOVER-FOXCROFT, Maine – While greenfield sawmill announcements have dominated the sawmill news cycle in recent years, another approach was being executed in the Northeastern corner of the U.S., where Pleasant River Lumber Co. was gathering lumber mills, timberland, and other diversified forest products interests like Southern squirrels do for the winter. Today, Co-Presidents and brothers Jason and Chris Brochu lead a family business of more than 800 employees, with major ongoing capital expenditure investments throughout multiple sawmills, while maintaining and building on a family culture that bodes well for the future. In addition, Brochu leadership and involvement in local and national affairs of the industry has settled into a family tradition as well.

Timber Processing gladly names Jason, 50, and Chris, 42, as the 35th annual recipient of the magazine’s Person of the Year award for 2023, marking the fourth time the award has gone to a lumberman in the state of Maine.

With a logging background, the Brochu family (four brothers including Chris and Jason’s dad, Adrian) first entered the sawmill business as Stratton Lumber in the early 1980s, building a sawmill in partnership with a Quebec family. In 2004, with Chris and Jason now in the fold, they purchased an antiquated sawmill operation in Dover-Foxcroft, Pleasant River Lumber, and began investing in machinery and production capacity, while selling out of the Stratton Lumber business.

The opportunistic growth strategy hasn’t stopped since in spruce-fir and pine lumber markets. In 2008, Pleasant River acquired an idled sawmill in West Enfield, Maine and in 2011 and 2012 purchased struggling mills at Ellsworth and Sanford, Maine. The two brothers became co-presidents after those purchases, and in 2015 when their biggest competitor for spruce raw material came up for sale, Moose River Lumber in Jackman, Maine, the purchase was a no-brainer.

The first in a series of diversification moves came in 2016, with the acquisition of Chaffee Transport, helping to control a seemingly uncontrollable part of the industry—trucking and logistics. The “COVID years” have seen more diversification, including the purchase of their aunt and uncle’s log home fabrication business, and acquisition moves into retail store and lumber distribution, meanwhile formally re-establishing A&A Brochu Logging, the original name of the family logging business started in 1968 which at the end of 2022 received the Maine Forest Products Council Outstanding Logger honor).

So, how does all of this work with two brothers? Both point to their age difference as a huge benefit. Jason has eight years on Chris, so while the two grew up together as brothers, Chris was just nine when Jason went off to college. Jason explains, after finishing his degree at Bentley University in Massachusetts, he “stayed away” working for other companies, doing other things. “When I am 30, he’s 22 and we come together to start working at Pleasant River. Before that we had never worked together. I think there’s an advantage there for us not having spent our entire lives growing up together. There’s no competition; we think alike. We both have our own things outside of the mill. We live in separate towns, but we work together every day.”

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.