SEPTEMBER 2022

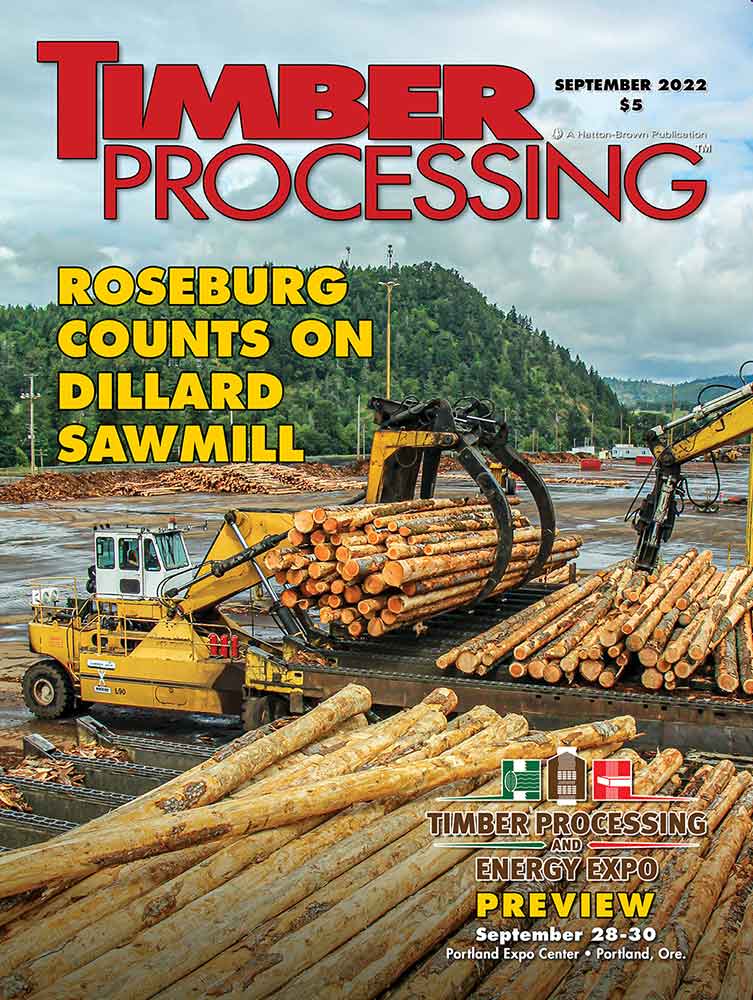

Cover: ROSEBURG COUNTS ON DILLARD SAWMILL

DILLARD, Oregon – Just before the turn of the century, the legendary Roseburg Forest Products founder Kenneth Ford rebuilt his sawmill here at Dillard, with a stud mill line that started up in 1998 after his death a year earlier. Four years later a reengineered and rebuilt end-dogging system with related breakdown equipment was added. The state-of-the-art sawmill facility broke the 400MMBF production mark in late 2013.

Inside This Issue

THE ISSUES: When Great Men Came Together

“Hallowed Ground” is a description reserved for Civil War battlefields, where large armies clashed and thousands of soldiers fell, and where great generals once stood—Grant at Shiloh and Lee at Fredericksburg. A sawmill is not on such a scale, but Roseburg’s at Dillard, Oregon comes pretty close.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Canfor Plans Alabama Sawmill

- Collins Names Insko President & CEO

- Western Forest Products Eyes Mass Timber Biz

- Mercer Purchases Germany’s HIT

- Softwood Lumber Board Reports Multiple Gains

- Sierra Pacific Industries Creates Wildfire Management Post

- New Sawmill Will Process Salvage Logs

- Income Was Down, But Still Strong

- Weyerhaeuser Pleased With Results

- Idaho Project Plants Seedlings

- Arsonist Act Destroys Machine

- Forest Service Officials Okay Twisp

SECOND LOOK: One Down

Our cover story in the May issue was the renovation of the former Anderson-Tully hardwood sawmill at Vicksburg, Mississippi into a high production southern yellow pine sawmill by Vicksburg Forest Products. It was no small task to say the least.

Get In Line

Following a pandemic-induced cancellation in 2020, the biennial Timber Processing & Energy Expo returns September 28-30 to the Portland Exposition Center in Portland, Oregon. Hatton-Brown Expositions, an affiliate of Timber Processing magazine, has hosted the event since 2010.

Productivity & Efficiency Conference

Co-located with the Timber Processing & Energy Expo in Portland, Oregon, Productivity & Efficiency: A Conference By Timber Processing, will be Thursday, September 29, 2022.

From Forest To Frame: Mass Timber Developments

Co-located with the Timber Processing & Energy Expo in Portland, Oregon, From Forest To Frame: Mass Timber Developments, will be Wednesday, September 28, 2022.

Timber Processing & Energy Expo Preview

EDITOR’S NOTE: The following companies, which are exhibiting in the TP&EE to be held in Portland, Oregon September 28-30, submitted editorial profiles to complement their advertisements placed in Timber Processing September 2022.

- AKHURST MACHINERY

- AMERICAN WOOD DRYERS

- BID GROUP

- BM&M

- BRUNETTE MACHINERY

- BRUNNER-HILDEBRAND

- BURTON MILL SOLUTIONS

- CARBOTECH (AUTOLOG)

- CLAUSSEN ALL-MARK

- COLONIAL SAW

- DELTA COMPUTER SYSTEMS

- EVERGREEN ENGINEERING

- FIBERPRO

- GILBERT

- GREG F SMITH

- HALCO

- HURST BOILER

- JOESCAN

- JOHN KING CHAINS USA

- LICO MACHINERY

- LIGNOMAT

- LINCK

- LMI TECHNOLOGIES

- METAL DETECTORS INC.

- MICROTEC

- MÜHLBÖCK

- NELSON BROS. ENGINEERING

- NYLE DRY KILNS

- OLESON SAW

- OPTICOM

- OPTIMIL

- PORTER ENGINEERING

- RAPTOR INTEGRATION

- RAWLINGS

- REAL PERFORMANCE MACHINERY

- SALEM EQUIPMENT

- SAMUEL CODING & LABELING

- SAMUEL PACKAGING

- S. HUOT

- SIGNODE

- SMITH SAWMILL SERVICE

- MID-SOUTH ENGINEERING

- TAYLOR MACHINE WORKS

- TELCO SENSORS

- TIMBER MACHINE TECHNOLOGIES

- USNR

- WAGNER

- VALUTEC

- VALON KONE

- VECOPLAN

- WELLONS

- WESTCOAST CYLINDERS

- WEST SALEM MACHINERY

- WILLIAMS AND WHITE

- WOOD-MIZER

MACHINERYrow

- LIMAB Enhances Downstream Scanning

- Cleereman Edger Hits The Mark

- LMI Smart Sensor Lives Up To Name

- Wood Fiber Group Is Burton Mill Solutions

- BID Group Launches Global Learning Center

ATlarge

- Roseburg Focuses On Real Estate Growth

- Monroe Joins ROM Leadership Team

- Sierra Pacific Foundation Comes Up Big

Find Us On Social

Roseburg Counts On Dillard Sawmill

Article by Dan Shell, Senior Editor, Timber Processing

DILLARD, Oregon – Just before the turn of the century, the legendary Roseburg Forest Products founder Kenneth Ford rebuilt his sawmill here at Dillard, with a stud mill line that started up in 1998 after his death a year earlier. Four years later a reengineered and rebuilt end-dogging system with related breakdown equipment was added. The state-of-the-art sawmill facility broke the 400MMBF production mark in late 2013.

Today, the dual-line design and much of Roseburg’s Dillard Lumber mill flow remains, but the level of technology and overall capacity surrounding and supporting the mill are light years ahead of Mr. Ford’s time. With the facility now capable of breaking 500MMBF in annual production of 8-, 9- and 10-ft. studs among the unprecedented challenges of a pandemic that helped create the highest lumber prices ever, Mr. Ford would no doubt be impressed with what his legacy has wrought.

Since Timber Processing last visited in 2005 after the major upgrade, Roseburg has pursued a compelling strategy of maintaining sawing technology and system upgrades along with investments in technology that empowers team members and helps build a stronger teamwork culture.

“We used to hire ‘sawmill people,’” says Dillard Lumber Operations Manager Marshall Ledbetter. “Now, we hire leaders and train them to do the job and give them what they need to do it.”

Some of the mill’s most recent equipment and system upgrades include:

- The #2 board edger received an optimization upgrade in 2021, with a new Goldeneye scanning and optimization package from MiCROTEC.

- In 2014-2015 several key investments were made, the first in July 2014 by adding a new USNR sawmill stacker that utilizes the MillTrak camera control system to monitor backlog and overall lumber flow.

- In 2019 the mill added its third American Wood Dryers (AWD) 84 ft. double-track kiln, this one with the Thermo-Vent features that reduces moisture and also gets the kiln up to temp quicker and helps hold it there, Ledbetter says.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.