JULY 2022

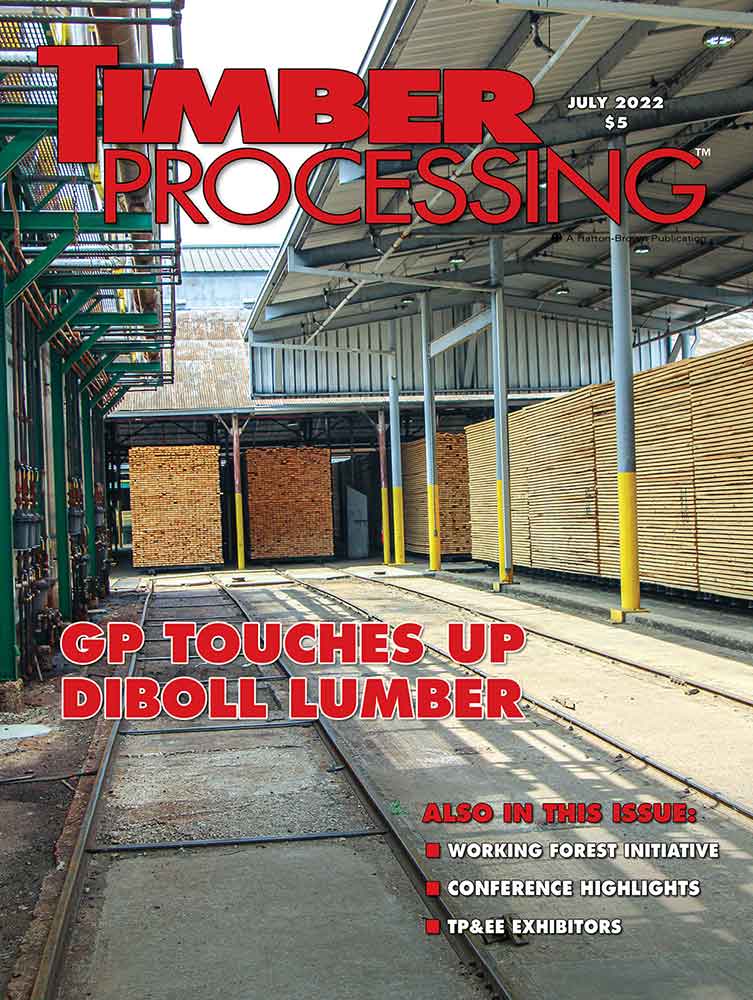

Cover: GP Touches Up Diboll Lumber

DIBOLL, Texas – After 125 plus years, a sawmill starts to show its age. But for Diboll Lumber, which is part of the impressive portfolio of SYP mills in Georgia-Pacific’s hat, age ain’t nothin’ but a number. Sort of. For Plant Manager Danny Wright, who started as an off-the-street hire as a young man, some of the machines might be vintage, but the heart of the plant beats strong. And that’s thanks to the dedication of the employee base; 185 are currently on staff.

Inside This Issue

THE ISSUES: Diboll Withstands The Test Of Names

Do you want to get confused? Let’s go to Diboll, Texas. Here you’ll find the Georgia-Pacific sawmill, which is our cover story this issue as written by Senior Editor Jessica Johnson.

That GP owns this sawmill, and has recently completed some upgrading to it, is the easy part. The difficult part is tracing back the history of the sawmill, and more specifically the number of ownership names that come into play, even if those names were mostly from the same company. See what I mean?

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- WWPA Conducts Annual Meeting

- New SYP Sawmill Stirs Up Dust

- Weyerhaeuser Led During Key Years

- PotlatchDeltic Plans New Mill

- Boise Acquires Coastal Plywood

- Agency Reveals Timber Actions

Timber Processing & Energy Expo Exhibitor's List

To view the TP&EE exhibitors visit timberprocessingandenergyexpo.com

Keynote Talks Highlight Conferences

ATLANTA, Georgia – Timber Processing affiliate magazines, Panel World and Wood Bioenergy, hosted close-coupled conferences in late March at the Omni Hotel in downtown Atlanta. The conferences—Panel & Engineered Lumber International Conference & Expo, and Wood Bioenergy Conference & Expo—combined featured 90 presentations and 125 exhibitors, including numerous keynote addresses.

MACHINERYrow

- ‘Strongest Link To Success’

- Elmsdale Lumber Announces Big Project

- BID Group Purchasing Smith Sawmill Service

- SmartMill USA Adds Two Employees

- HALCO Honored For Operations Research

- Deere Names Forestry President

- BID Starts Up Facility Expansion

- Versowood Plans Boiler Upgrade

- TEC Is Named Sennebogen’s Best

- Weinig Launches Investment Program

ATlarge

- Price Becomes 75th Forest Products Society President

- Biewer Enhances Sales Department

- Softwood Lumber Board Supports Wood Innovation Grants

- American Wood Protection Association Elects Archer As President

PRODUCTscanner10

- Fulghum Expands Product Line

- FiberPro Builds On Experience

- Sennebogen Lineup

Find Us On Social

Georgia-Pacific Touches Up Diboll Lumber

Article by Jessica Johnson, Senior Associate Editor, Timber Processing

DIBOLL, Texas – After 125 plus years, a sawmill starts to show its age. But for Diboll Lumber, which is part of the impressive portfolio of SYP mills in Georgia-Pacific’s hat, age ain’t nothin’ but a number. Sort of. For Plant Manager Danny Wright, who started as an off-the-street hire as a young man, some of the machines might be vintage, but the heart of the plant beats strong. And that’s thanks to the dedication of the employee base; 185 are currently on staff.

Wright says, “We’ve added some pieces and upgraded, but the majority of the equipment is ’99 model. What’s the secret? It’s the people. We’ve got multi-generational employees working here. It’s their community, they want to see it flourish. We’ve kept it going for a lot of years.” That pride in the beating and banging that often goes hand-in-hand with operating a sawmill that has been different “sawmills” since Temple-Inland first opened, and a recent string of capital investments has maintained Diboll Lumber’s place on the sawmill map, increasing capacity to 280MMBF and securing its place as a modernized mill.

But even with those investments, Wright is quick to stick to his (and the mill’s) roots. The latest and biggest investment since 1999 was to two of the facility’s batch dry kilns—essentially bringing them up to current Wellons specs.

And thanks to the re-tube and re-skin of Diboll’s existing units, the batch kilns aren’t breaking down as frequently as they once were. What was the biggest bottleneck in the mill was handled with a 16-day shutdown of the boiler and kilns with more than 100 contractors on-site. By re-tubing, replacing all the sheet metal (re-skinning) these two Wright says are basically new. “And we moved our bottleneck from the kilns to making the sawmill feel the pressure,” Wright laughs.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.